Food & Beverage

Food & Beverage

Fruit extraction, Sugar & Starch, Breweries and Pet Food

ANDRITZ supplies ready-to-install components and custom solutions. A wide range of manufacturing technologies, experience acquired over decades and sound know-how about our customers’ production processes guarantee maximum reliability and ongoing optimization of your production.

An overview about our broad portfolio:

Breweries & Beverages

Products for Breweries, Malteries & the Beverage Industry

Filtration components for breweries and the production of beverages

False bottoms and filter candles

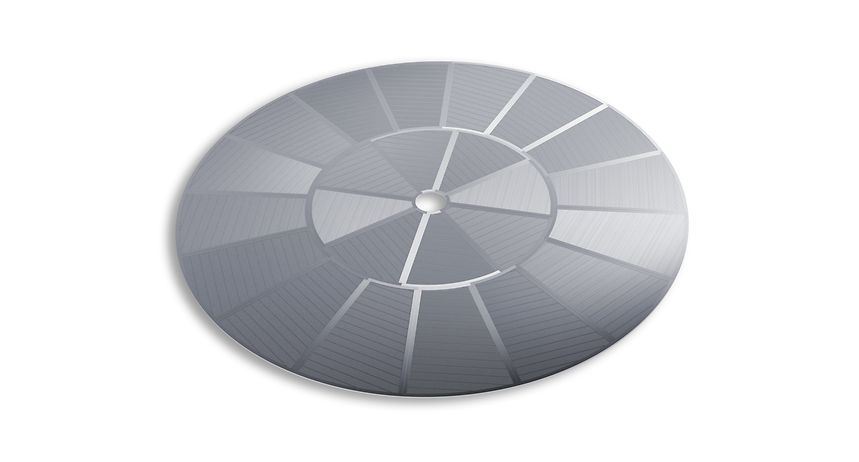

From traditionally milled lautering false bottoms “Made in Germany” through malting floors for malt houses to modern wedge wire screen bases for lautering, we manufacture perforated or wedge wire screen bottoms in all designs.

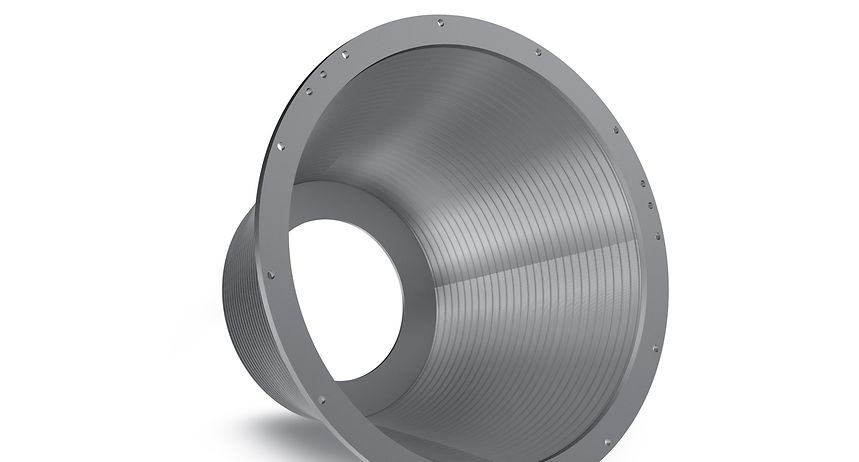

False bottoms

In brewing technology, the lauter tun is where the wort is separated from the remains by wedge wire or slot milled screens. Wedge wire screen strainers provide a larger open area and therefore a higher throughput. ANDRITZ false bottoms have slot widths with very low tolerances for ideal filtration results.

Segmented false bottom

Filter candles

Our wedge wire screen cartridges offer accurate separation results and high flow rates and can be used in a wide range of filtration stages with different viscosity levels. Our wedge wire screen candle filters have even proved effective in diatomaceous earth filtration.

In mixing and dosing processes, e.g. for beverage concentrates, the rugged design of our products ensures high process availability and a long service life.

Filter candles made of wedge wire

Coffee & Cacao Processing

Products for Coffee & Cacao Processing

Components for coffee and cocoa processing lines

Cylinders, mill baskets and screen cartridges

Ready-to-install components from ANDRITZ meet the stringent requirements of the foodstuffs industry in every respect and ensure highest quality in the production process. All ANDRITZ components are free from lead and tin.

Cylinders for granulating instant coffee

Perforated screens in the shape of cylinders are used when coffee is granulated. Depending on process and tolerances, drilled or punched perforations are selected.

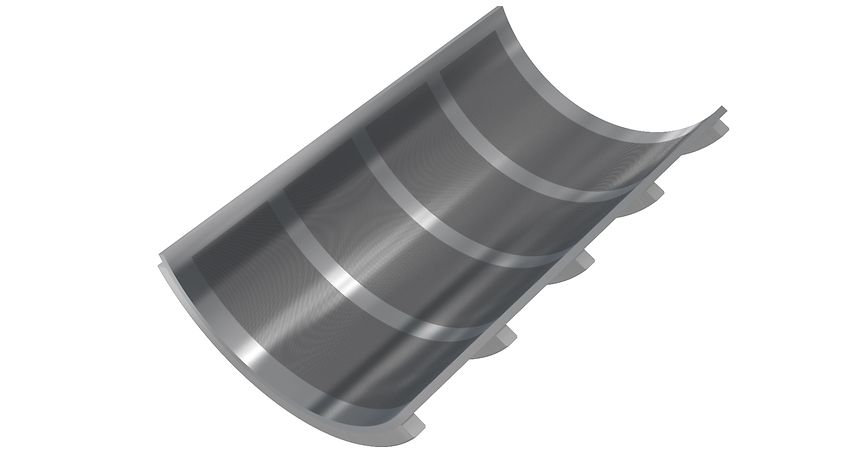

Cocoa mill baskets

Output fineness and wear life of cocoa mill baskets are the production`s key parameter.

ANDRITZ screen baskets for cocoa mills combine excellent output fineness and outstanding wear life.

Detailed View of a Wedge Wire Basket

Wedge wire screen cartridges for smooth chocolate products

Thanks to accurate separation results and high flow rates our wedge wire screen cartridges can be used in a wide range of filtration stages with different viscosity levels. The component provides excellent output fineness.

Filter candles made of wedge wire

Pet Food

Products for the pet food industry

Components for the pet food production

Hammer mill screens

Many factors define the quality of pet food: Besides the quality of the raw material, the processing is an important step in the production of pet food. ANDRITZ delivers hammer mill screens made of ConiPerf for steady hackling and a uniform output for further processing.

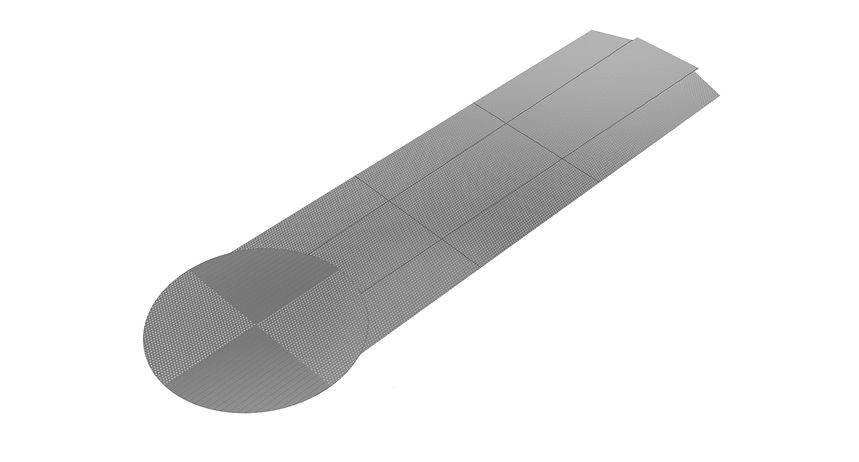

Hammer mill screens

ANDRITZ hammer mill screens for food and pet food processing is made of stainless steel with a ConiPerf rasp perforation with holes from 0,5 to 2,5 mm. These mill screens are optimized to fit your mill with maximum output rate and a very long lifetime. When it comes to processing very hard raw material, ANDRITZ hammer mill screens can be nitrate-hardened for even longer lifetime.

Mill Insert with ConiPerf Rasp Perforation

Rice & Grain

Products for rice mills and grain processing

Components for the Grain & Rice Processing

Mill screens, rice grading and polishing screens, trieur sorting screens

Perforated and trieur sheets for sorting, special perforated sheets for cleaning and screening, components with ConfiPerf perforation for husking: we offer a large number of machine components suitable for various applications in the processing of grains, rice and cereals.

Hammer mill screens

ANDRITZ hammer mill screens for grain and rice processing is made of stainless steel with a ConiPerf perforation. These mill screens are optimized to fit your mill with maximum output rate and a very long lifetime. When it comes to processing very hard raw material, ANDRITZ hammer mill screens can be nitrate-hardened for even longer lifetime.

Mill Insert with ConiPerf Rasp Perforation

Screens for rice graders and rice polishers

Rice graders and rice polishers are punched plates or plates with ConiPerf perforation. They are usually made of stainless steel and are nickel- and tin-free to comply with food safety regulations. The screens are delivered with mounting holes and ready for installation.

Rice polisher screen with punched oblong holes

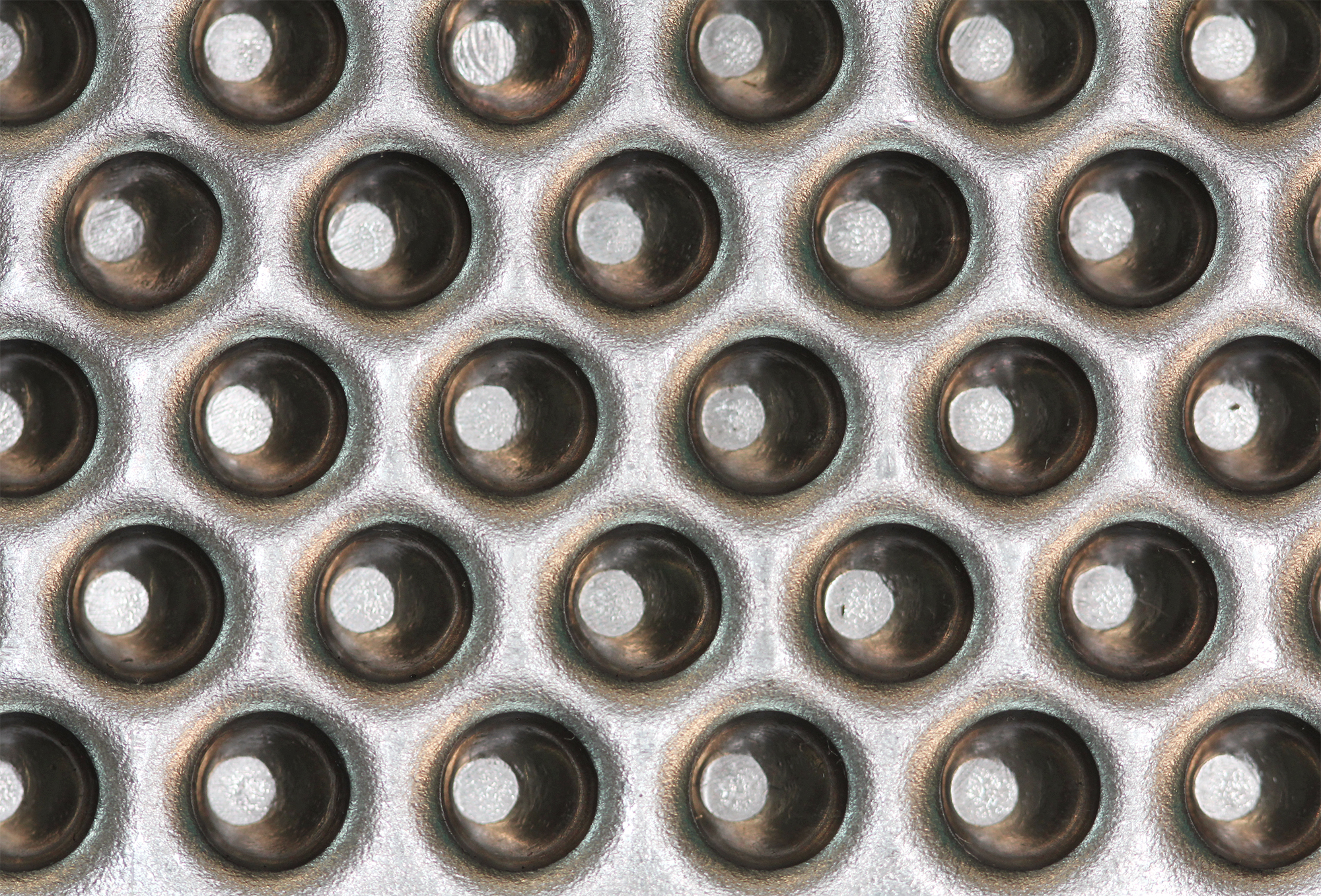

Trieur sorting screens

Trieur screens are used to sort and separate seeds in order to get the same size and weight for further processing. The embossed surface of trieur screens can be configured to your demand regarding size and shape of the processed raw material. ANDRITZ trieur screens are optimized for higher throughput due to minimized space between the embossed surface.

Trieur Screen

Starch

Products for the starch industry

ANDRITZ components for the starch industry

DSM Screens, conical screens and half screens for screw presses

ANDRITZ has a broad portfolio of components for the starch industry. As a manufacturer with all technological possibilities, ANDRITZ delivers the following components:

ANDRITZ starch industry components

- 120° Bent Screens (DSM) used in in corn wet milling for fiber washing

- Drilled screw press baskets (half-screens, cylindrical or conical baskets) for fiber and germ dewatering

- Conical centrifuge baskets, made of wedge wire, ConiPerf, or drilled

120° bent screens (DSM screens)

Exact slot widths are crucial in the manufacturing of starch. That’s why all our products are camera-controlled to ensure the tightest slot width tolerances are kept. The surfaces of our bent screens can be polished to increase the surface smoothness and quality.

120° Bent Screen (DSM screen)

Conical centrifuge baskets

Centrifuges are used for solid-liquid separation. An efficient separation process is particularly important. ANDRITZ wedge wire screen baskets are designed with a focus on high performance and longer service life through optimized open area and wear resistant material.

Conical screen

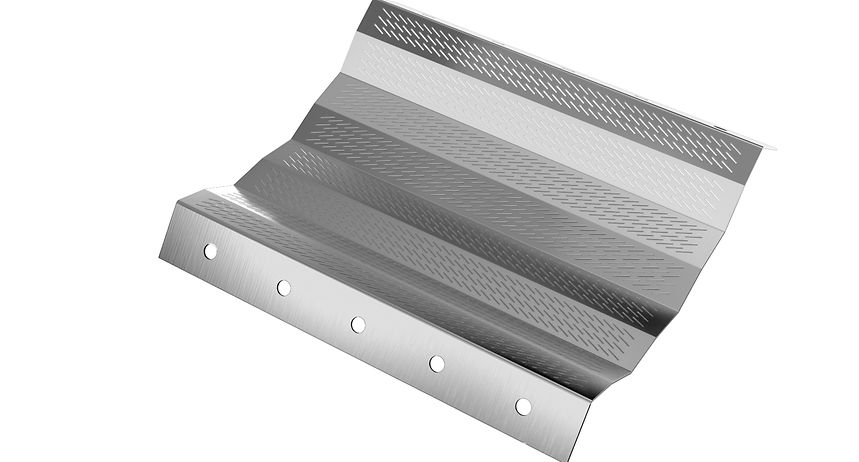

Screw Press Baskets

ANDRITZ screw press baskets are available with all variants of slot widths and come with different features depending on your application:

- Solid

- Split in different variants

Alternatively ANDRITZ also offers screen plates in the design variants flat, straight grooved or slanted grooved.

Half screen for screw presses

Sugar

Products for the beet and cane sugar production.

Components for the sugar industry

Screens for sugar pulp presses, centrifuge screens and distribution beds for fluid bed dryers

ANDRITZ has a broad portfolio of components for the sugar industry. As a manufacturer with all technological possibilities, ANDRITZ delivers the following components:

Drilled screens for sugar pulp presses

Drilled screens for the sugar industry offer the best dewatering — allowing you to reduce energy costs and maintenance requirements.

A maximum number of holes and the correct hole geometry minimize the risk of clogging and delivering the best dewatering results with the lowest energy consumption for drying.

In addition to the number of holes, another important aspect of dewatering is the correct gap between the screw and the screens in the press.

Drilled screens have a long life and are very stable, minimizing deformation. This is due to the structural design and the proper selection of wear-resistant stainless steel alloys to perfectly match your process requirements.

Drilled half screen for sugar pulp presses

Punched screens for sugar pulp presses

Pulp press screens have hole diameters down to 1 mm with a maximum punched plate thickness of 1 mm. The thinness of these plates is compensated for by adding supports to the frame. However, these frames also reduce the open area of the screen, reducing the dewatering efficiency when compared to a drilled screen.

The following punched screens are available for common types of sugar pulp presses:

- Thin screens with small hole diameters

- Supporting screens in thick material with large punched holes

- Deaeration screens with large open area and different hole shapes, e.g. flapped holes

ConiPerf distribution beds for fluid bed dryers

Distribution beds made of ConiPerf plates are the first choice in any fluid bed application (e.g. sugar dryers or coolers).

- ConiPerf ensures that sugar is directed in a defined path and will not fall through the holes

- Different plates or segments with defined flow directions can be arranged within one distribution bed

- ConiPerf plates are supplied to match the pressure drop required by the process

- Smooth operation and less damage to the sugar crystals

ConiPerf Fluid Bed Dryer

Screens for extraction towers type DDS

Screens for extraction towers type DDS are either produced in punched, drilled, or slot-milled segments. The most common are milled segments with slots of 1,2 x 190 mm in 4 – 5 mm thickness or drilled segments with conically drilled holes with 2:3 mm diameter in plates of 2,5 – 3 mm thickness.

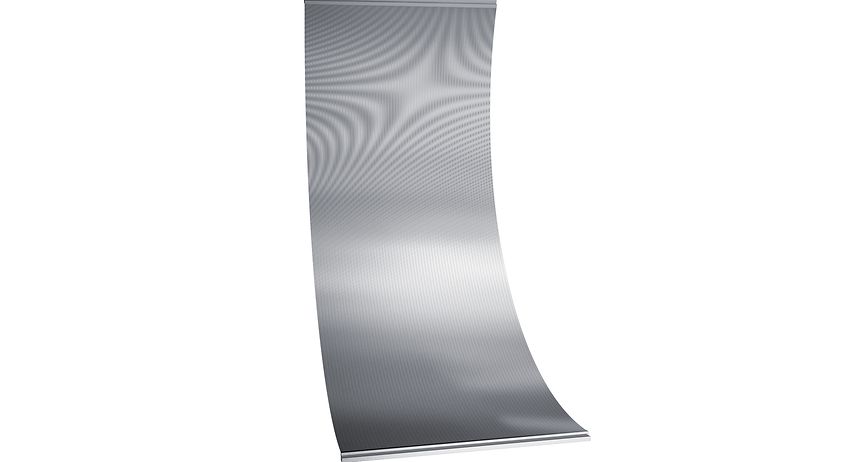

Screens for crystallization centrifuges

MicroPerf screens made of chrome-plated stainless steel with slots 0,06 or 0,09 mm wide are a slightly more expensive, but significantly more efficient alternative to galvanized chrome-nickel screens used in crystallization centrifuges.

MicroPerf screens feature additional benefits:

- Free open area of up to 9 %

- Longer lifetime: 400-800 %

- Improved molasses yield / improved sugar yield

Continuous centrifuge screens

Polished wedge wire screens with continuous horizontal slots ensure rapid separation of the sugar crystals from the molasses and allow a smooth flow of crystals across the surface of the screen without the secondary damaged traditionally caused by short, vertical slots. Using a polished, continuous wedge wire with horizontal slots ensures that the crystals do not break up.

- Higher sugar retention

- Rapid separation of the sugar crystals from the molasses

- Wear resistant

- Higher profitability

- Low maintenance costs

Tomato & Fruit extraction

Products for tomato, fruit and vegetable extraction.

Separation components for the processing of fruit and tomatoes

Drilled and punched fruit extraction baskets

Our straining machine baskets are used in the production of tomato paste as well as fruit and vegetable concentrates. For this purpose our rotary screens remove suspended matter and residues from process water.

Our tomato baskets are manufactured in two variants:

Drilled baskets for the highest screening efficiency

Drilled holes can have the following geometries:

- Cylindrical

- Conical

- Bicylindrical

When drilling, a high quantity of small holes down to 0.4 mm (.016”) in thick plates can be realized, with microperforation even down to 0.1 mm (.004”). This gives the baskets a very high open area, high stability and if required smallest hole diameters at the same time.

Drilled tomato screen basket

Punched baskets for the lowest replacement costs

Punching is the most economical perforating technology. Depending upon plate thickness, holes can be punched down to 0.4 mm (.016”). Due to our perforating performance punched baskets show high open areas. The lack of stability in thin plates is corrected by using cages or punched backup baskets, although the use of reinforcements will reduce the open area compared to drilled baskets.