Meat processing

Meat processing

In addition to fresh meat, which

In addition to fresh meat, which

have undergone the refrigeration without the adding of additives (as only thermal treatment for the conservation), there is the processed meat (meat products and meat preparations) where the conservation is possible through thermal treatments as cooking, smoking etc.

Tinned meats and cured meats are really appreciated on the Italian market and for them are used different systems for meat conservation.

Canning is a process which permits meat conservation thanks to procedures in autoclaves which sterilize the product in hygienic conditions and appropriate temperature and pressure. The cans are then sterilised in autoclaves where they remain about one hour at a temperature of 120° (sterilisation).

On the contrary, meat products are prepared as whole pieces or as fresh meat mixture and inserted in natural or synthetic casings to which are added ingredients as salt, pepper and other spices to permit the conservation over the years. The products stored inside a casing are called “insaccati” (cured meats).

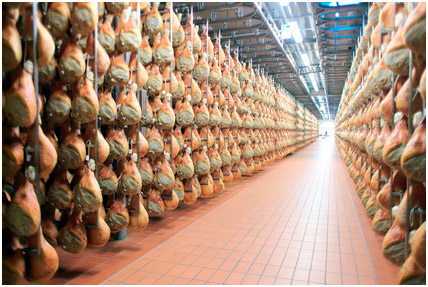

Cold cuts are stored in conditioned and aired rooms for 15-90 days, according to the product, with a temperature of about 12°C: if they are aged cured meats they are stored immediately after casing, if they are fresh products, after the drying and cooling process inside refrigerate rooms.

The first phase is called stewing (temperatures between 18 and 26 °C for 1-4 days). Then follows the drying (5-10 days) in order to guarantee the conservation.

The aging last from 4 to 8 weeks (or more) with a temperature of 10-15°C. After the aging the surface moulds are removed through brushes or washing the product.

In case of cooked salami (mortadella) the product is stored inside stoves where the heating means is 85°C air. After the cooking, the cold cut is immediately cooled until an internal temperature of 10°C.

The Vienna sausage for example is a cooked salami, sometimes smoked, sold with or without peel, packed and pasteurized (over 70°C for 15 minutes).

Ham production first of all requires the selection of the thigh from the rest of the pig and after a good cleaning it will be deboned. Then it will be salted and subsequently formed and cooked with steam and water at 100°C (1 hour for every kg of product) and the cooling at 0°C for 24 hours, then they are vacuum-packed.

Speck comes from pig’s thigh, without bone and cold-smoked (max 20°C) for 3 weeks.

Valtellina’s Bresaola is a cold cut which comes from salted and aged beef meat. The salting time is from 10 to 20 days. After the washing and stuffing process the meat is dried in specific cells. Then follows the aging at a temperature of 12 and 18°C, for 2/4 months.